Craftsmanship and creativity

RESEARCHOUR MILESTONE AND OUR GOAL: IMPECCABLE QUALITY.

All our products are made in Italy. Our workshop is where ideas take shape and turn into precious leather goods.

The research of raw materials is the first step to the creation of a high quality product. We select our leathers and hides scrupulously, with a demanding eye for high standards, from tanneries in Tuscany where the millenarian tradition of vegetable tanning is combined with state-of-the-art technology.

The manufacturing process

PRODUCTION STEPSFROM LEATHER SELECTION TO THE FINAL HOTSTAMP.

Each project starts from leather selection. Every hide is unique and one-of-a-kind for it consistency, veining, colour and texture, like a fingerprint. The knowledge and experience of the Cutting Operator (Tagliatore) are therefore fundamental in order to pick out the most refined part of the hide.

After the first quality check, when possible small imperfections of the hides are spotted and marked, the leather is ready to be cut in long stripes or in the desired shape.

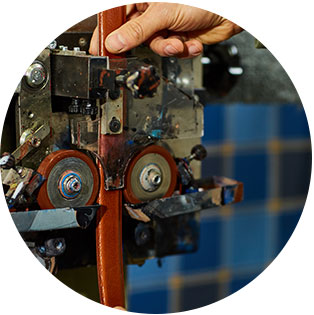

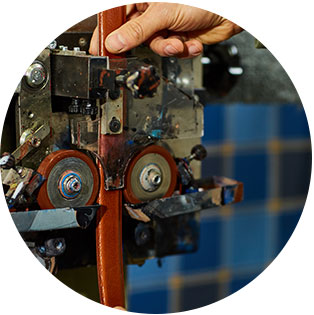

01 | SKIVING

Mechanical skiving grants consistent thickness to the leather stripes, providing an even base for the following shaping step. Both top stripe “dritto” and bottom stripe “fodera” are shaped to match and create a precise design.

02 | GLUEING

Top stripe and bottom stripe are then sealed together with glue both manually and with specific machineries. It is at this point that the item takes its belt form.

03 | DYEING

Dyeing the belt’s borders produces two kinds of result: technically, the dye fills up the leather pores and vitrifies the surface, which becomes surprisingly smooth to the touch; style-wise, it enhances the belt’s character: matching the leather colour for a classy and timeless accessory, contrasting for a vibrant and more daring style. No limits to customization possibilities!

04 | SEWING & STITCHING

Sewing and stitching enrich the appearance of the product. Delicate ornamental stitching with sober and light threads for classics and “marcapunto” heavy stitching, zigzag seams, double stitching and brighter colours for sporty and eclectic styles.

05 | FINISHING

The choice of buckle and metallic accessories matching the belt’s personality is the styling’s process completion step.

Last but not least, a specific heat printing machine marks each and every single product with our distinctive claims: “Genuine Leather” and “Made in Italy” as well as technical information such as waist size, total length and height in mm.

All throughout the production process the products’ quality is monitored in order to correct possible defects. A final quality control is carried out at the end of the production line to make sure all accessories comply with our strict standards.

01 | SKIVING

Mechanical skiving grants consistent thickness to the leather stripes, providing an even base for the following shaping step. Both top stripe “dritto” and bottom stripe “fodera” are shaped to match and create a precise design.

02 | GLUEING

Top stripe and bottom stripe are then sealed together with glue both manually and with specific machineries. It is at this point that the item takes its belt form.

03 | DYEING

Dyeing the belt’s borders produces two kinds of result: technically, the dye fills up the leather pores and vitrifies the surface, which becomes surprisingly smooth to the touch; style-wise, it enhances the belt’s character: matching the leather colour for a classy and timeless accessory, contrasting for a vibrant and more daring style. No limits to customization possibilities!

04 | SEWING & STITCHING

Sewing and stitching enrich the appearance of the product. Delicate ornamental stitching with sober and light threads for classics and “marcapunto” heavy stitching, zigzag seams, double stitching and brighter colours for sporty and eclectic styles.

05 | FINISHING

The choice of buckle and metallic accessories matching the belt’s personality is the styling’s process completion step.

Last but not least, a specific heat printing machine marks each and every single product with our distinctive claims: “Genuine Leather” and “Made in Italy” as well as technical information such as waist size, total length and height in mm.

All throughout the production process the products’ quality is monitored in order to correct possible defects. A final quality control is carried out at the end of the production line to make sure all accessories comply with our strict standards.